Long term environmental stability

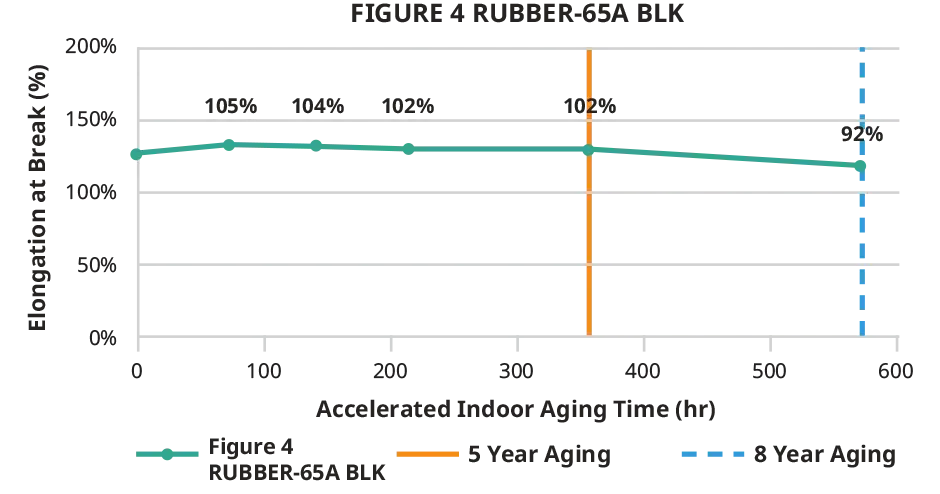

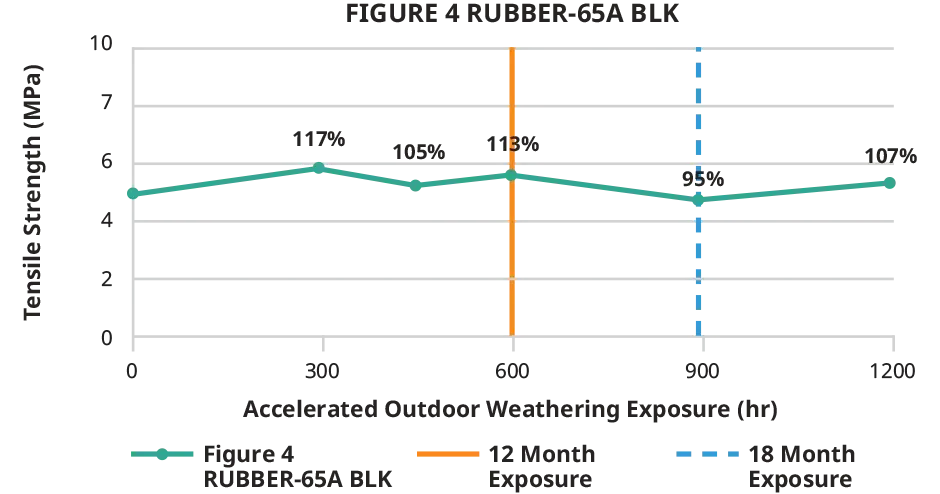

Figure 4 RUBBER 65A BLK is engineered to give long term environmental UV and humidity stability. This means the material is tested for the ability to retain a high percent of the initial mechanical properties over a given period of time. This provides real design conditions to consider for the application or part.

The chart shows a sampling of the dataset. The full datasheet includes Indoor and Outdoor Stability data for Tensile Strength, Elongation at Break, Tensile Modulus and Impact Strength. Actual data value is on Y-axis, and data points are % of initial value.

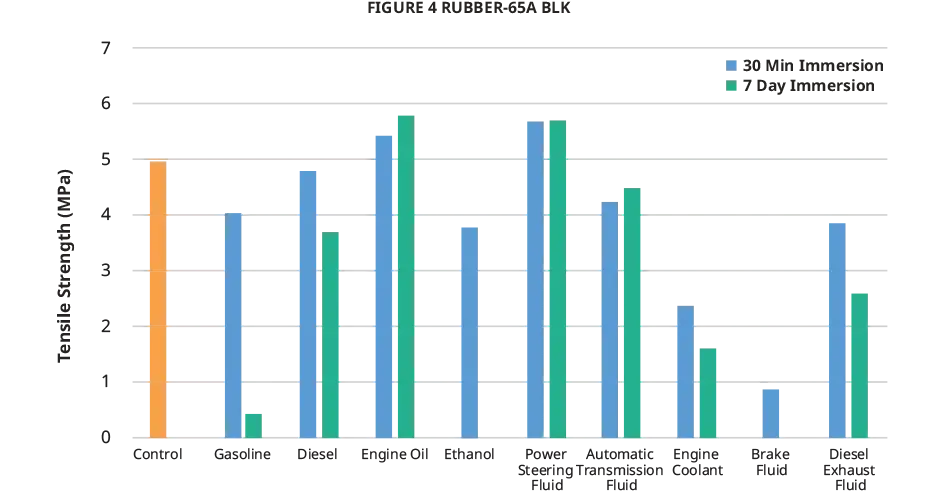

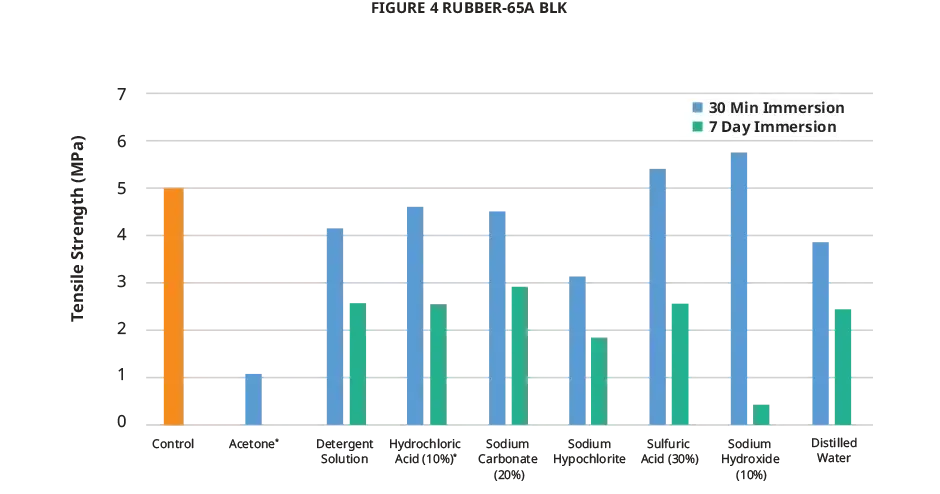

Chemical and automotive fluid compatibility

The compatibility of a material with hydrocarbons and cleaning chemicals is critical to part application. Figure 4 RUBBER 65A BLK parts were tested for sealed and surface contact compatibility per ASTM D543 test conditions and per USCAR2 test conditions. Tensile Strength (MPa) is shown below. The full datasheet includes additional data tables for Tensile Modulus, Elongation at Break and Notched Impact Strength.

* Note: Not all products and materials are available in all countries – please consult your local sales representative for availability.

Warranty/Disclaimer: The performance characteristics of these products may differ according to variations in printing and post processing conditions, test equipment, product application, operating conditions, or with end use. 3D Systems makes no warranties of any type, express or implied, including, but not limited to, the warranties of merchantability or fitness for a particular use.

What's New with Figure 4?

こちらもご検討ください

技術仕様

この素材と互換性のあるプリンター:

Figure 4 Production

ダイレクトデジタル生産に対応した業界初のカスタマイズ可能な完全統合型ファクトリーソリューション

Figure 4 Modular

ビジネスの成長に合わせて拡張できるように設計されたスケーラブルな半自動 3D 製造ソリューション

Figure 4 Standalone

即日プロトタイピングや少量生産を高速に低コストで実現