マルチジェット材料の多様な選択肢

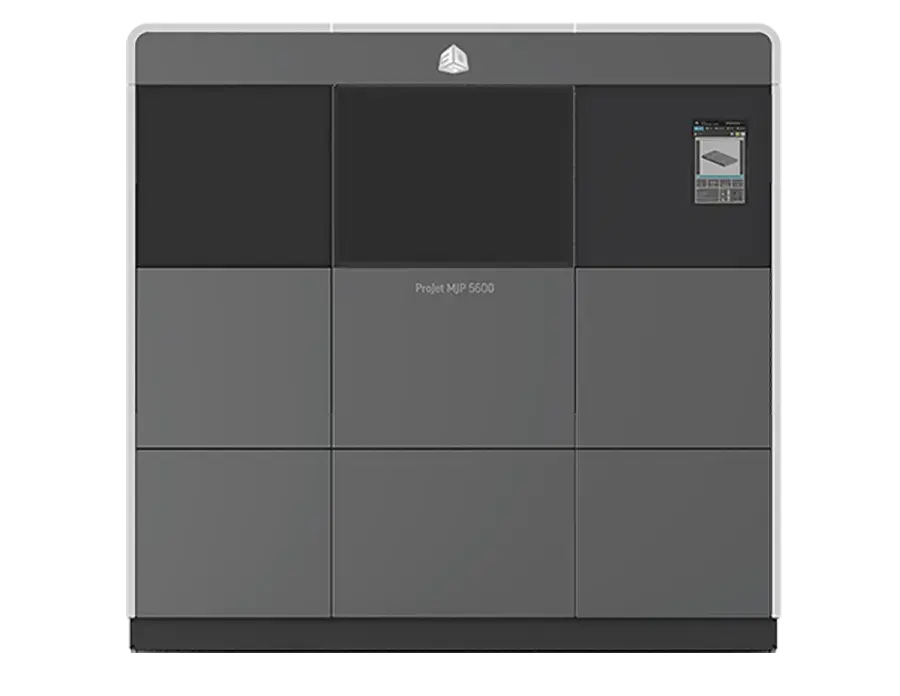

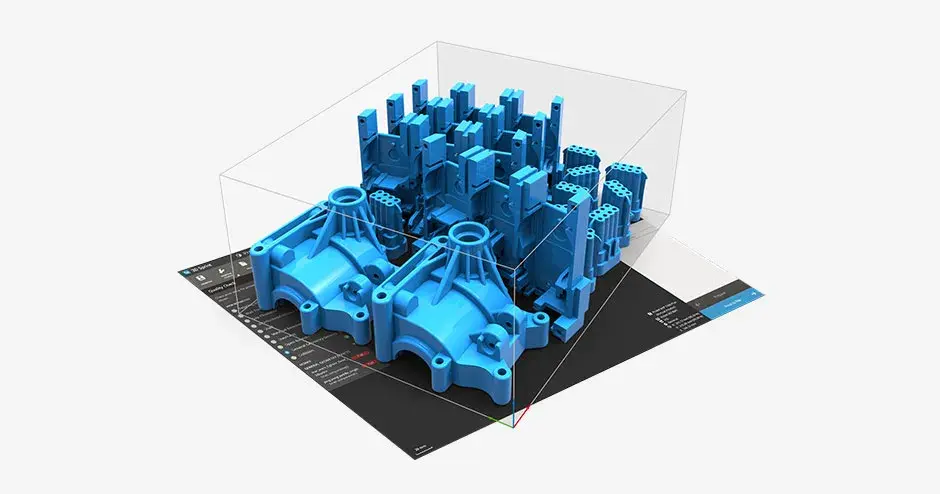

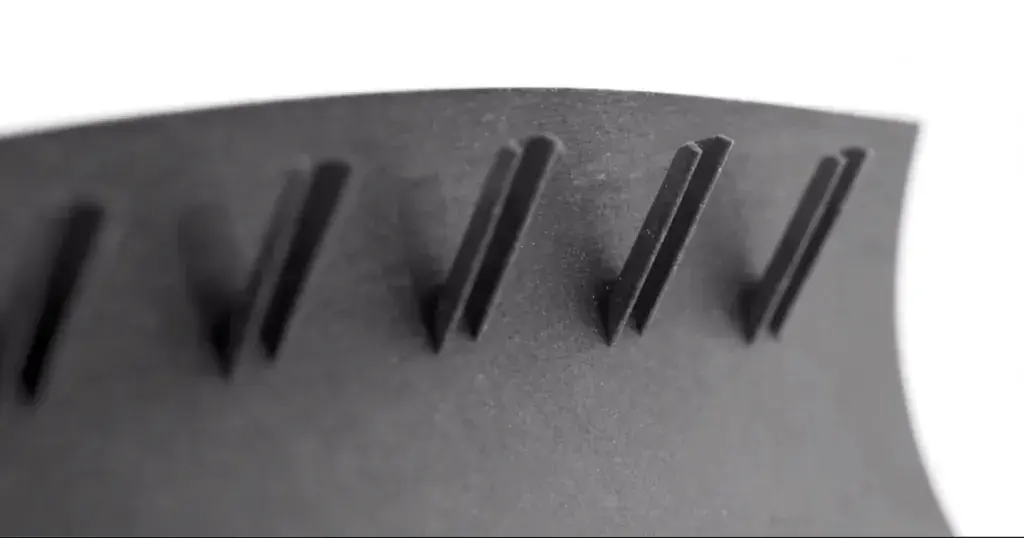

The ProJet® MJP 5600 MultiJet 3D プリンターソリューションは、VisiJet® ファミリーの材料のうち、柔軟なフォトポリマーと剛性のフォトポリマーをブレンドしながらプリントします。これを 1 つの部品、1 回の造形ごとにボクセルレベルで一層ずつ行い、優れた機械特性を実現します。さらに、VisiJet の剛性プラスチック、エラストマー、複合材料は、1 つの部品でさまざまなレベルの柔軟性や材料の透明性を備えているうえ、色調を変えることができます。