Register Now

Recognized over the years for its exceptional prototyping quality and part accuracy, SLA-based additive manufacturing is changing in a big way, with an automation-ready solution that offers up to twice the print speed and up to three times the throughput of existing SLA systems.

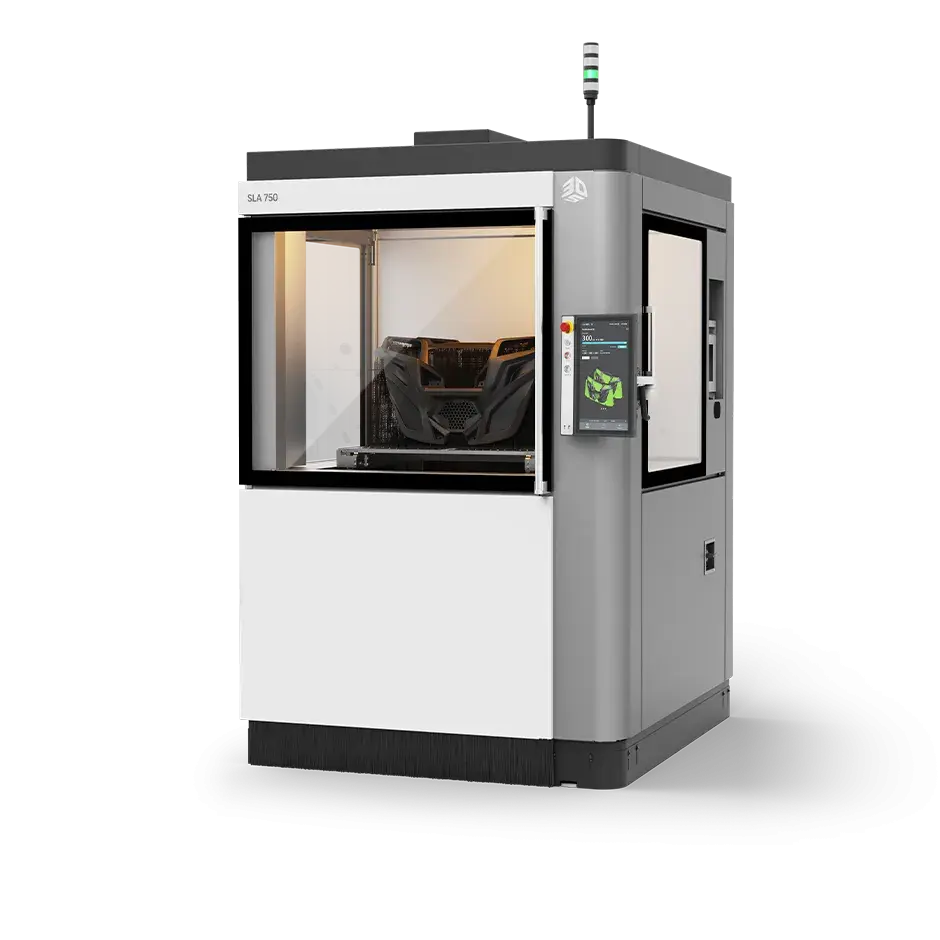

Join us as we reveal the revolutionary innovations that we are introducing with our new SLA 750 full workflow solution. Providing breakthrough gains in speed, throughput, material performance, and cost-efficiency for factory-floor production, this complete solution features production-grade materials, automation compatibility, and AI-based seamless integration with all factory floor equipment. These innovations now more effectively answer your requirements, from prototyping to production, whether you are a service bureau, automotive, aerospace, consumer goods, foundry or medical device manufacturer.

Meet the Expert

David Leigh

Executive Vice President, Chief Technology Officer for Additive Manufacturing,

3D Systems

David has more than 30 years of experience in the additive manufacturing industry. Prior to his role with 3D Systems, David served as the Chief Technology Officer (global) and Chief Operations Officer (North America) for EOS. He also founded Harvest Technologies which was a pioneer in end-use parts applications in aerospace and established one of the first AS9100 certified additive manufacturing facilities. Harvest was acquired by Stratasys in 2014, and David transitioned to the innovation and technical teams, serving as the Senior Vice President of Emerging Technologies.

David holds a PhD in Materials Science and Engineering, a Master of Science in Engineering, and a Bachelor of Science in Mechanical Engineering, all from the University of Texas at Austin, a pioneering research university in additive manufacturing.

おすすめ製品

SLA 750

工業スケールの光造形向け積層造形ソリューション